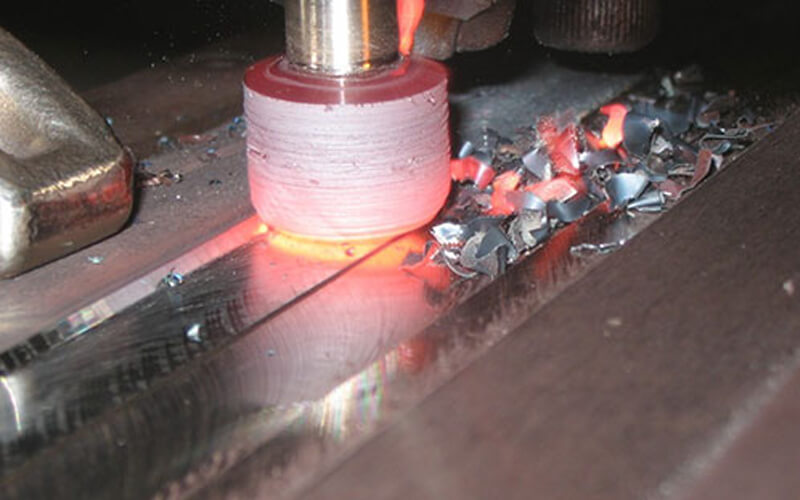

Discover how you can benefit from Frictec's unique TMC 45 Friction Surfacing Technology.

Materials and Coatings

In addition to our unique TMC45 material, we also offer a range of other high-performance materials and coatings.

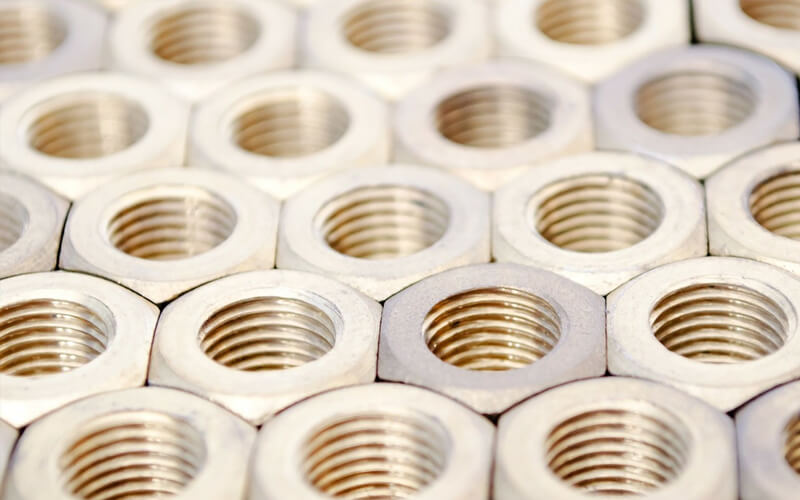

For each application we manufacture we can offer the most appropriate material for your production and, where necessary, apply a surface coating to help improve your production efficiency. Materials regularly used include:

- TMC45

- Carbide insert on a SS420 substrate

- Tool Steels: N690, Calmex, M2, M42, D2

However, with our extensive experience in this field we can source other more approriate materials, where required, to enable us to offer the optimum product.

The range of specialist coatings we commonly offer, and the specific benefits each of these brings, can be seen here below. In addition to their individual benefits, each of these coatings will help improve the overall productivity of your parts leading to reduced downtime and decreased maintenance costs:

WC/C (Nitron MC)

A dry lubricant reducing the accumulation of film residue on your part.

- Anthracite grey coloured protective coating

- Coefficient of friction (0.1-0.15)

- Surface hardness 1000Hv micro hardness

- Coating thickness 2-4um

- Performs effectively in temperatures up to 300°C

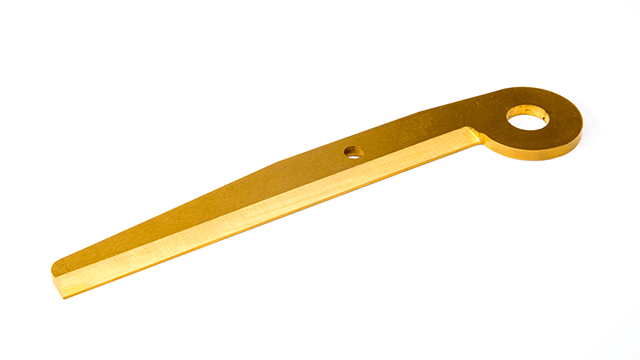

TIN (Titanium Nitride)

Increasing the hardness and edge retention of your part.

- Yellow/gold coloured protective coating- suitable for direct food contact

- Surface hardness 2300Hv micro hardness

- Coefficient of friction 0.4

- Coating thickness 2-4um

- Performs effectively in temperatures up to 500°C

AlTiN (Aluminium Titanium nitride)

Increasing the hardness and edge retention of your part (for extreme heat conditions)

- Blue/black coloured protective coating

- Surface hardness 3300Hv micro hardness

- Coefficient of friction 0.4

- Coating thickness 1-4um

- Performs effectively in extreme temperatures of up to 800°C

- h

- h

- h

- h

- h

Coatings such as Teflon, CrN and others are also available, depending on your individual requirements.