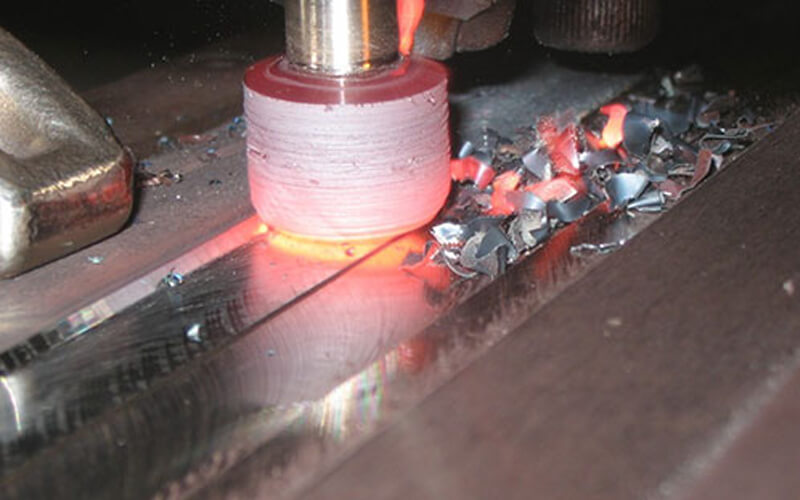

Discover how you can benefit from Frictec's unique TMC 45 Friction Surfacing Technology.

Research and development

Frictec is the only company able to offer Friction Surfacing on a commercial basis and has many years experience applying the technology to practical wear applications.

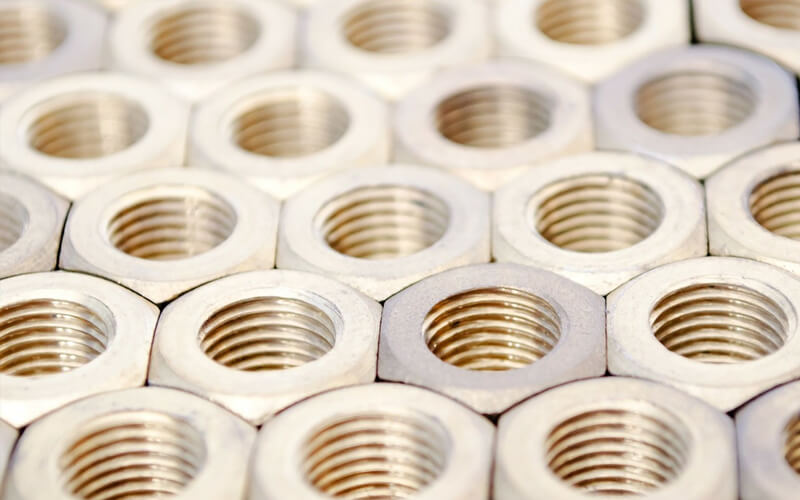

We develop the process and its capabilities with our in-house R&D team working in cooperation with various industrial and academic partners. With our specialised equipment and dedicated R&D facility, Frictec is able to develop ideal composite materials for new applications. With the appropriate material selection, specific characteristics can be obtained to achieve:

- Improved wear resistance

- Protection against corrosion

- Homogenous repairs to valuable components

- Desired thermal/electrical conductive properties

Wide ranges of component sizes and geometries have been successfully coated and many materials, including specialist alloys, have been investigated and analysed. An extensive database has been established, which has led to the development of sophisticated process modelling software used to help predict process parameters for new materials.

Machine capabilities include depositing steel mechtrode diameters from 2mm-32mm with linear tracks as long as 2m in a single run.

The following examples show some of the geometries that have been successfully Friction Surfaced.

- Onto a flat surface

- Into and edge or central recess

- Pre-formed hole spot deposits

- Precise location deposits