Discover how you can benefit from Frictec's unique TMC 45 Friction Surfacing Technology.

Coffee and Tea Industry- Sachet Knife Success

1st January 1970

The brief:

Frictec was approached by a large blue chip company manufacturing sachets of coffee based products. At the time, this company was experiencing considerable down time issues and challenging cut quality problems.

The result:

Following a visit to the factory, where samples of the knife applications were provided, a clear understanding of the machine operation and challenges faced was achieved.

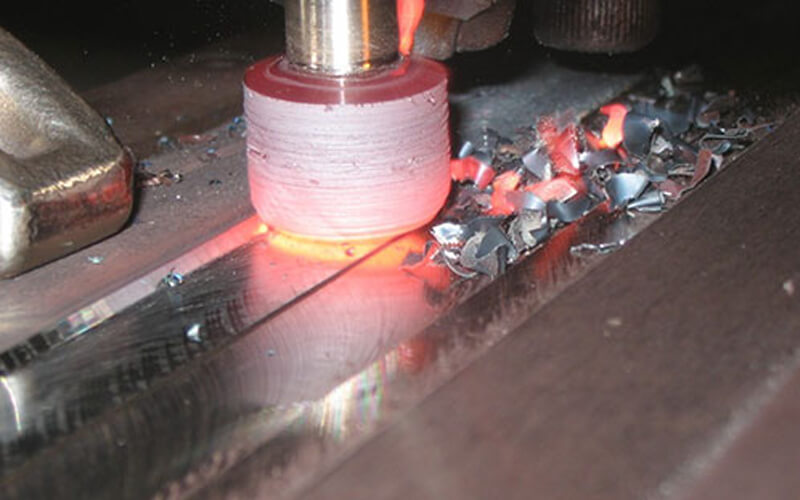

Frictec then reverse engineered the problematic knives, re-designing them to enable the use of the unique TMC45 material. Following this, quantities were manufactured for a controlled trial.

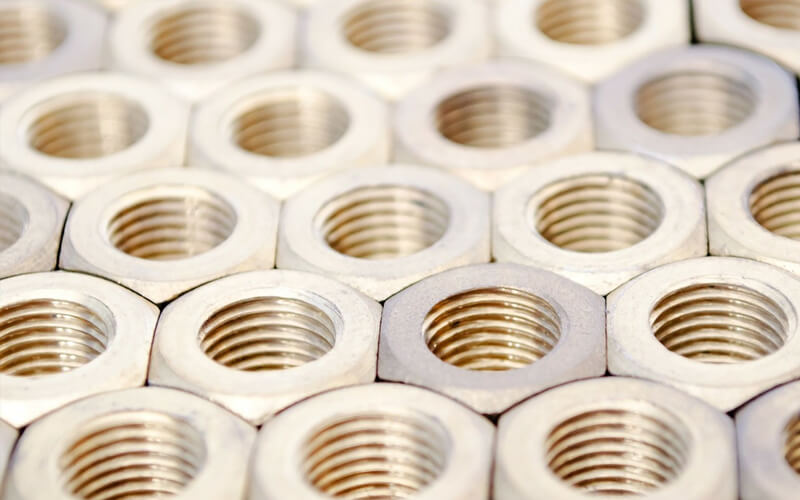

The result achieved with the new design and material was a great success. Knives that previously required constant adjustment and re-setting along with monthly replacement, now achieve between 9 and 12 months life, as well as very minimal and infrequent adjustment.

Measurable results were provided in many areas:

1- Reduction of annual spend on replacement knives

2- Reduction of machine down time, due to less time needed for re-setting and fewer knife exchanges

3- Improved cut quality, less dulling of the cutting edge providing better quality products

4- Savings on maintenance hours, and in turn maintenance costs