Closures, Caps and Plastic Extrusion Industry- Tamper Evident Slitter Success

1st January 1970

The brief:

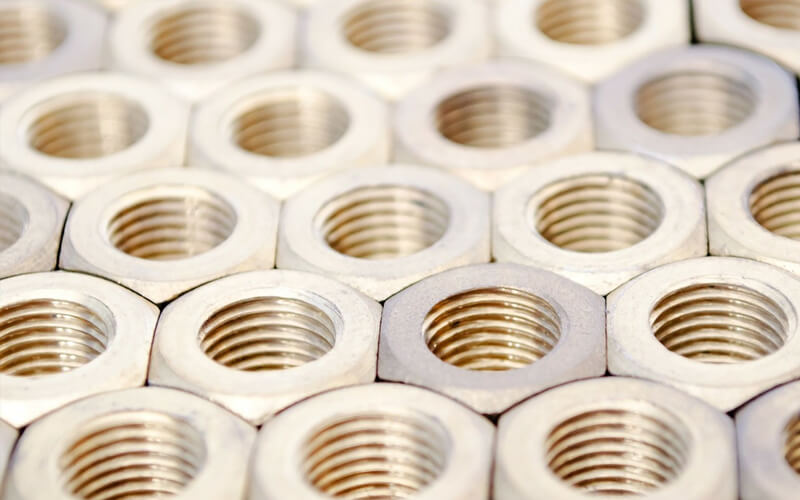

Frictec support a global company manufacturing caps and closures for a wide range of tamper evident applications. This is a niche market and requires very high tolerance control measures.

The result:

Frictec are able to support this company with both production slitters and also development projects.

Visiting sites in both the UK and internationally allowed Frictec to have a very good understanding of the technologies and machinery used in tamper evident cap production. We were tasked with new size caps, material changes and cap design alterations. Being able to manufacture smaller quantities and batch sizes with short trial lead times allowed Frictec to face and successsfully rise to the challenges given by this company.

Measurable results were achieved in many areas:

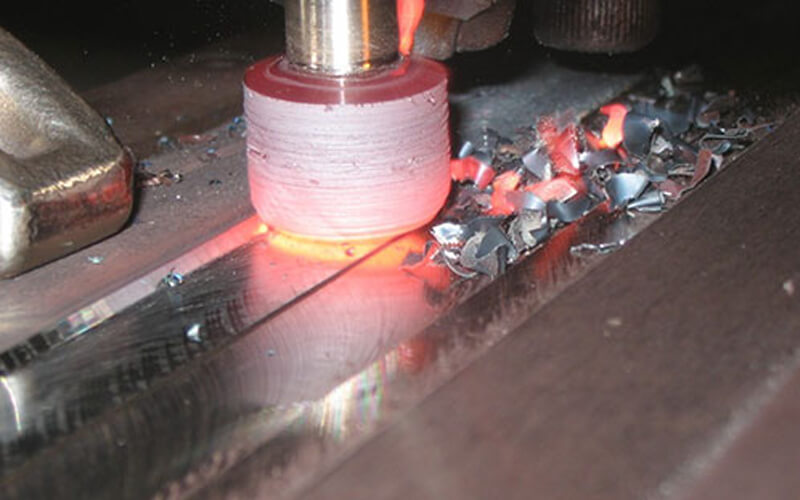

1. By applying specialised surface coatings surface hardness was increased and a reduction in product residue adhesion was achieved- This lead to improved production efficiency and longer lasting blades.

2. Reducing lead times but pre-manufacturing standard blanks that are heat treated and part prepared for final finishing processes.

3. Providing many years of manufacturing experience to improve cutting quality, altering design, radius parameters and notch profiles along with material upgrades.

4. Sharing best practice across factories, allowed shared benefits and group production efficiency improvements.