Continuously developing the processes and capabilities with our R&D team, in cooperation with various partners.

Services

Frictec offers a number of services to its customers to assist production demands, and improve knife and wear part performance where required. There are also many measures taken to ensure that customer satisfaction is at its highest level.

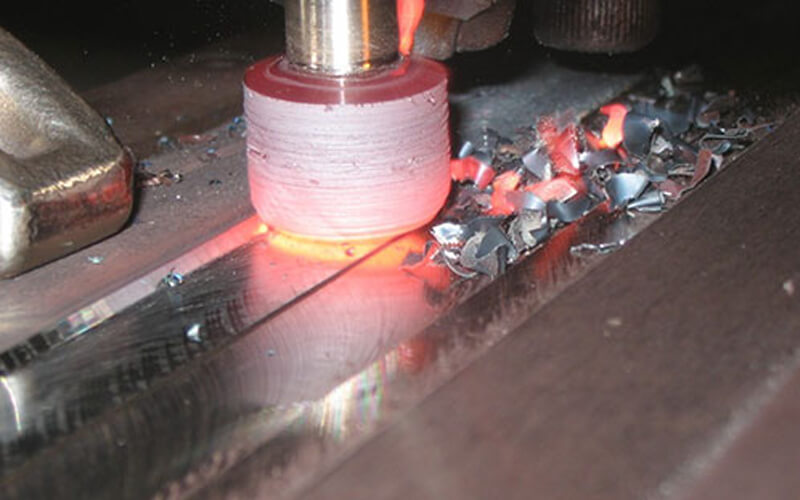

At Frictec we ensure that all our products are being designed and manufactured to the highest level of quality.

Frictec has many years of experience in servicing parts, offering regrinds and refurbishments on site, with a lead time of 2 weeks.

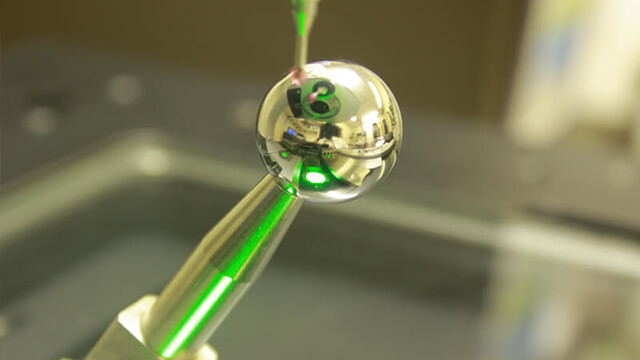

Frictec can offer specialised materials and coatings to support various applications and extend the life of your parts.

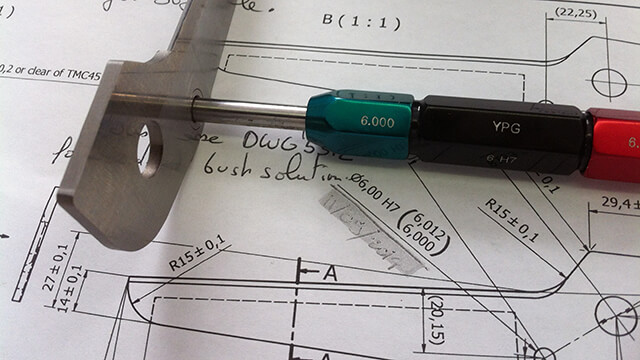

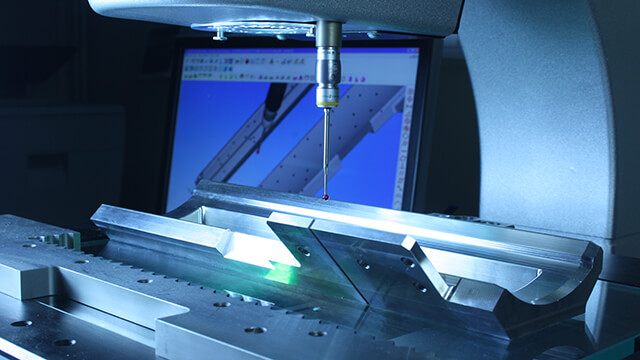

Frictec offer reverse engineering services, with state of the art measuring equipment, recreating parts from just a sample or drawing.

We like to visit our customers production sites to understand their needs, find solutions to technical issues and discover greater business opportunities.