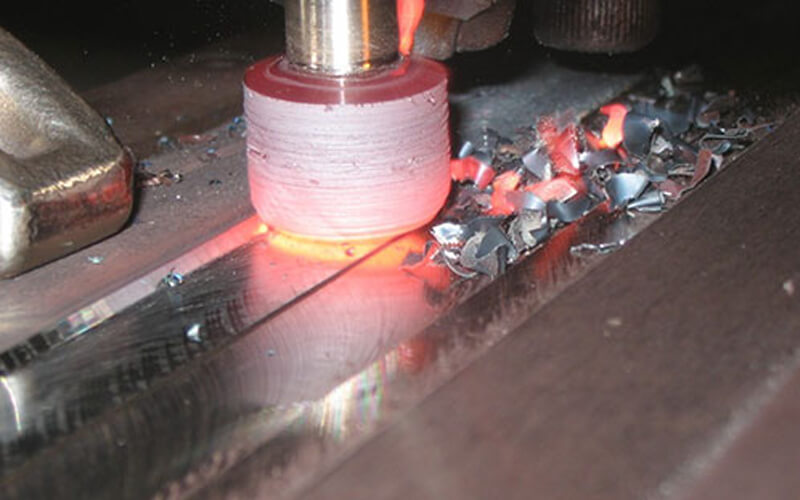

Discover how you can benefit from Frictec's unique TMC 45 Friction Surfacing Technology.

Quality & Design

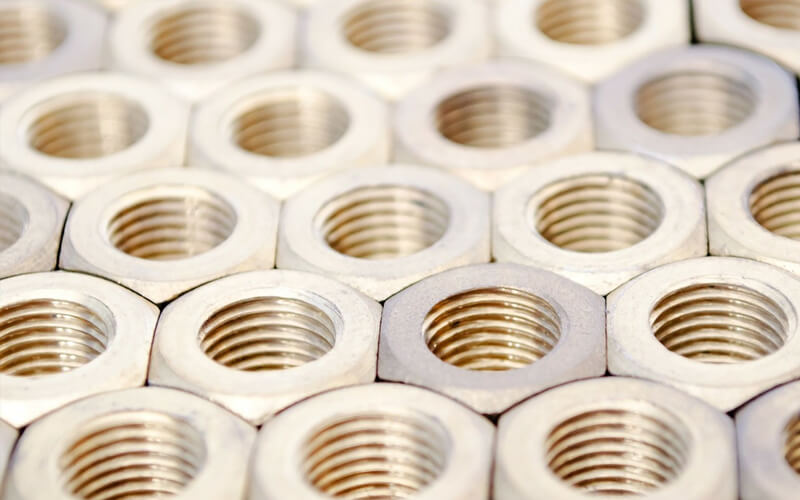

Quality is of the utmost importance at Frictec. Our exceptional products and services have seen us awarded with the ISO9001:15 certificate every year since it's introduction.

Our strict quality assurance procedures are applied throughout production, including during the friction surfacing process. Frictec operates a system specifically tailored to your needs, certified to ISO9001 quality standards. You can view our ISO9001:15 certificate here. Friction surfacing is a very controllable process with the repeatability and reliability of modern machine tool technology.

Quality assurance throughout the manufacturing process ensures the highest quality parts are consistently supplied. State of the art inspection equipment allows us to accurately measure all component dimensions to the finest tolerances. Equipment such as the CMM (Coordinate Measuring Machine), sophisticated profile projectors and microscopes enable us to not only inspects accurately but also to precisely reverse engineer parts from customer samples.